CNC Machining

CNC Milling

A machine process which produces custom-designed parts or components by progressively removing material from the workpiece using rotating multi-point cutting tools and computerized control.

CNC Milling Operations

Milling, threading, chamfering, grooving etc. It is suitable for many different features including. This allows complex designs to be produced with enviable accuracy in a single CNC milling center. CNC machining tolerances are approximately +/- 0.1mm.

Surface milling

Plain milling is also commonly known as face milling. It uses a horizontal cutter, that is, the axis of rotation of the cutting tool is parallel to the cutting surface.

Face milling can use different cutters, wide or narrow, depending on the required result. Using a wide cutter, combined with the cutter's slow cutting speed, fast feed rate, and coarse teeth, can result in rapid material removal. Of course, the surface finish of this type of cut may not meet thea requirements.

Therefore, a second step may involve changing tools to use finer threads. This also requires higher cutting speeds and slower feed rates, so the amount of material removal per unit time is slower. At the same time, the final finish is more accurate. Therefore, the combination of the two makes it a good choice economically.

Face milling

This process uses a cutting tool with teeth on the sides as well as on the tip. The axis of the tool is perpendicular to the machined part. Face milling often comes after face milling as it can produce more complex contours and leave a pleasant finish. The teeth on the sides do most of the cutting work, while the teeth on the end do the finishing work.

Angular milling

This milling process includes chamfers, grooves etc. It allows us to create. There are several ways to achieve these features. In the case of a normal 3-axis milling cutter, it makes most sense to use different cutters. These can be dovetail cutters to create angled grooves or a milling cutter with a tapered cutting head for chamfering only. Notice that these two are fundamentally opposite to each other. The cutter's axis can be vertical or flush with the surface.

Form milling

This milling process allows us to create chamfers, grooves etc. There are several ways to achieve these features. In the case of a normal 3-axis milling cutter, it makes most sense to use different cutters. These can be dovetail cutters to create angled grooves or a milling cutter with a tapered cutting head for chamfering only. Notice that these two are fundamentally opposite to each other. The cutter's axis can be vertical or flush with the surface.

Profile milling

A common milling process to produce convex and concave parts. The process includes 3 steps - roughing, semi-finishing and finishing. Roughing uses round inserts to do the first job to remove most of the material. Ball nose end mills are perfectly suited for semi-finishing and finishing. 4- and 5-axis technology will greatly benefit from CNC milling as it can speed up processes significantly and provide better quality.

Gear milling

Yes, milling also finds use in producing different types of gears. The entire gear manufacturing process consists of two steps. Gear milling comes first. The softness of the material makes the part easier to create while achieving large tolerances. The gears then go through a heat treatment process to harden the surface. After that, CNC turning will be responsible for the final result.

Swiss Turning

Extremely tight tolerances and More comples parts

Originally designed for the watch-making industry, Swiss machines have exploded in popularity within precision manufacturing. This is because Swiss-type lathes are uniquely capable of producing extremely small, precise parts at a rapid pace.

Benefits of Swiss Turning

The combination of high precision and high production volume make Swiss machines a critical piece of equipment for shops that must produce a large volume of small and intricate parts with little margin for error.

Extremely tight tolerances

Swiss machines firmly support the workpiece right next to the point of operation throughout the machining process. Because the piece is supported so close to the tooling operation, the part remains steady, virtually unaffected by the force of the tools. This ensures precision within extremely tight tolerances—even when machining very small parts.

More Complex Parts

Because of how well the bar stock is supported throughout the machining process, Swiss machines can also produce more intricate parts with thinner walls, more delicate features, and deeper cuts that would not be possible on other machines.

Fast Pace

The cycle time for a Swiss machine can be significantly shorter than other types of CNC machines. Where other machines may require an hour or more to machine a single part, Swiss machining can produce upwards of 30 parts per hour, depending on the size and complexity of the part.

Ready-to-Ship Parts

Swiss machines produce such a fine and precise result that these machines can reduce or eliminate the need for secondary operations, often resulting in parts that are ready to ship right out of the machine.

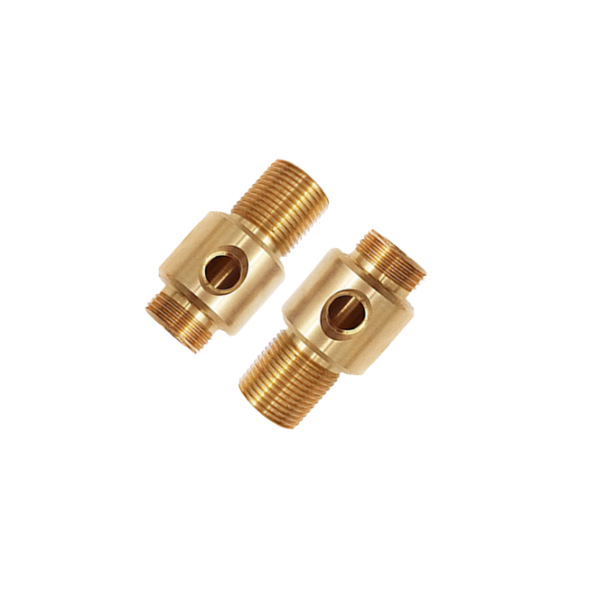

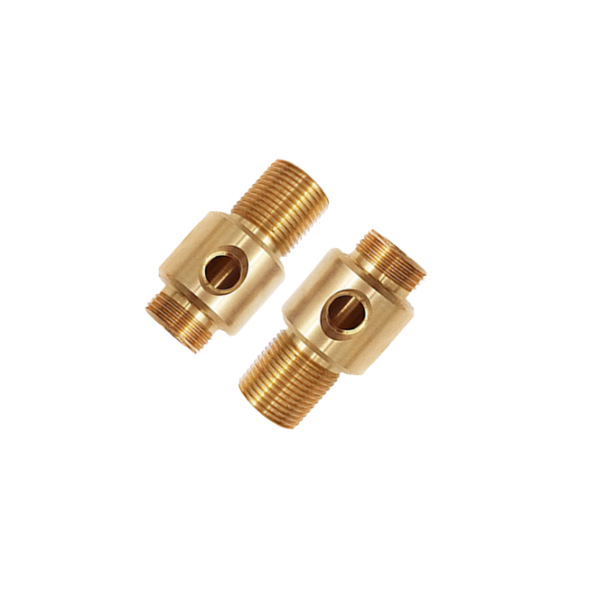

CNC Turning

CNC Turned Parts From Single To High Volume Mass Production

That is, the part is rotated while a single point cutting tool is moved parallel to the axis of rotation. Turning can be processed on the external surface of the part as well as internally, which is also called boring. The material used for this production is generally a work piece generated by other processes, such as casting, forging, extrusion or drawing.

Types of CNC Turning

Few specific turning operations, such as tapered turning, spherical generation, hard turning, facing, parting, and grooving, will be explained below. These are Non-specific operations, such as boring, drilling, knurling, reaming, threading and polygonal turning will be explained below.

Boring

Boring is the process of enlarging a hole that has already been drilled (or casted), by means of a single-point cutting tool (or of a boring head containing several such tools), for example as in boring a gun barrel or an engine cylinder. Boring is used to achieve greater accuracy of the diameter of a hole, and can be used to cut a tapered hole. Boring can be viewed as the internal-diameter counterpart to turning, which cuts external diameters.

Drilling

Drilling is the process used to remove material from the inside of a work piece. This process utilizes standard drill bits held stationary in the tail stock or tool turret of the lathe. The process can be done by separately available drilling machines.

Knurling

The cutting of a serrated pattern onto the surface of a part to use as a hand grip using a special purpose knurling tool.

Reaming

Reaming is the sizing operation that removes a small amount of metal from a hole already drilled. It is done for making internal holes of very accurate diameters. For example, a 6mm hole is made by drilling with 5.98 mm drill bit and then reamed to accurate dimensions.

Threading

Both standard and non-standard screw threads can be turned on a lathe using an appropriate cutting tool. (Usually having a 60, or 55° nose angle) Either externally, or within a bore. Generally referred to as single-point threading. tapping of threaded nuts and holes.

Polygonal turning

When turning polygons, part and Automatic head turns to steer. Cutter head rotates twice the speed of the track with its one sharp directions are a pair of equal angles apartments in location. The meaning is: the number of apartments concerned polygon is twice the amount from the cutting edges.