Horizontal milling machine

Let’s take a look at what constitutes a milling machine. While the new milling centers are capable of handling all kinds of operations, they are also more complex. That’s why we adhere to more traditional machines here to provide an overview of machine components.

Horizontal milling machines get their name from the positioning of the tool – their axis is horizontal. The pictures above show one way to use them, this is straight milling. Of course, horizontal mills are also suitable for end milling.

The construction of a horizontal mill is quite simple. The cutting tool is attached to the arbor. If a change to the tool is required, you can remove the shaft bracket and spacers to change tools.

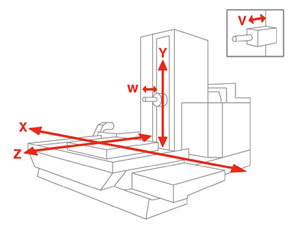

Fixing the workpiece to the work table requires a vise. The traverse can move the table in the X, Y, and Z-axis to move the workpiece.

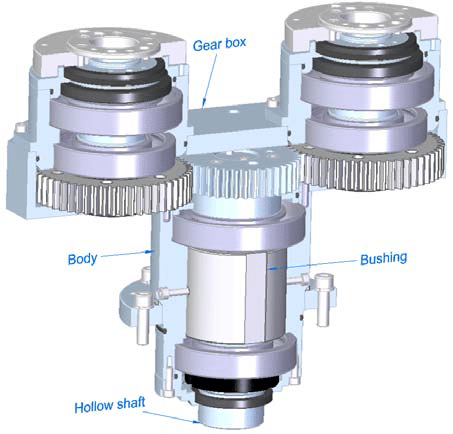

Of course, the new machines look a little different, which makes them suitable for automation. Horizontal milling centers can have several spindles with various tools for faster turning times. In addition, the table and tools can move in more directions, including rotary axes.

Still, the basics are enough to understand the same and more traditional machine, to make sense of contemporary ones.

Possibility to produce parts with less process

The ability to create more complex parts

Approximately 3-4 times faster than vertical milling

Longer tool life

Better surface finish